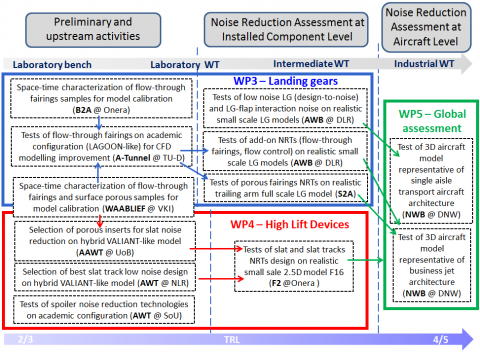

The INVENTOR experimental programme will be based on a series of complementary wind tunnels for smart and cost-optimized use, with two fundamental objectives :

- to rapidly and rationally select the best NRTs and low-noise designs, and better understand their efficiency and

- to provide validation data for the improvement of all involved numerical approaches.

TRL-oriented rationale of the experimental workflow in laboratory, intermediate and industrial facilities

To implement this experimental programme, INVENTOR will rely on the following facilities :

Laboratory facilities, often used to check validity of concepts at lowest cost, are made of typically centimetric test sections and/or anechoic chambers, equipped with a large range of microphones arrays, static pressure probes, Particle Image Velocimetry (PIV) and Laser Doppler Velocimetry setups. In INVENTOR, two families of laboratory wind tunnels will be involved:

Small benches (B2A at Onera and WAABLIEF at VKI) will be used to measure the space time characteristics of the flow-through fairings and the surface inserts manufactured from innovative porous materials involved in passive NRTs for LGs and HLDs. These data are mandatory for the calibration of the numerical models that are under continuous development for implementation in the CFD solvers.

Small aeroacoustic wind tunnels will be used for preliminary and upstream activities linked to LGs (A-Tunnel at TUD) and HLDs (AWT at NLR, AAWT at UoB, AWT at SoU) to rapidly evaluate the most promising configurations of NRTs, with only limited aerodynamic considerations, mainly based on noise maps, farfield spectra and directivity patterns, on small scale isolated airframe elements. These facilities are very useful to check and optimize innovative ideas and to better understand the underlying physical principles of noise reduction.

Intermediate wind tunnels such as AWB at DLR (for LGs) and F2 at Onera (for HLDs) are made of metric veins for aeroacoustical measurements under static flow. They allow measuring semi-installed models of airframe components, thus taking into account basic installation effects and also leading to noise maps, farfield spectra and directivity patterns in far-field acoustic environment and operational conditions typical of fully-installed models.

Industrial wind tunnels like the NWB (operated by DNW on a DLR’s site) and the S2A are typically used for higher TRL developments (4 and 5) and eventually for industrial purpose (TRL 6). In INVENTOR, they will allow testing full scale aircraft components (landing gear in S2A), or full aircraft models integrating several airframe components whatever they have been “designed-to-noise” or they embark NRTs. They are therefore valuable to characterize so-called “installation effects” (i.e. interaction of various parts possibly leading to new noise sources) in realistic flight conditions, at least for take-off and landing, when noise is of paramount importance. Moreover, thanks to microphones arrays and individual microphones combined with sophisticated signal treatment and processing techniques, they allow for localizing, identifying and quantifying actual noise sources and the overall noise footprint of the aircraft model or component.

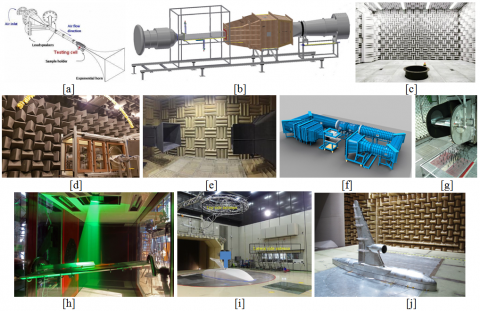

Facilities involved in INVENTOR.

1/ Small laboratory benches: B2A at Onera [a], WAABLIEF at VKI [b].

2/ Small laboratory wind tunnels: A-Tunnel at TU-D [c], AAWT at UoB [d], AWT at UoS [e], AWT at NLR [f].

3/ Intermediate aeroacoustic wind tunnels: AWB at DLR [g], F2 at Onera [h].

4/ Industrial facilities: S2A [i], NWB at DNW/DLR [j]