Flow-through porous fairings for landing gear noise reduction :

experimental characterization in WAABLIEF (VKI) and B2A (ONERA) windtunnels

INVENTOR focusses on porous flow-through fairings implemented in front of landing gear to decrease noise. Targeted concepts are wiremeshes, perforated plates and metallic wool. One of the objectives is to numerically simulate these fairings in CFD/CAA solvers, which requires to experimentally characterizing how they modify the mean flow velocity and the turbulence intensity and structure. Such characterization has been achieved in two combined facilities, WAABLIEF at VKI and B2A at ONERA.

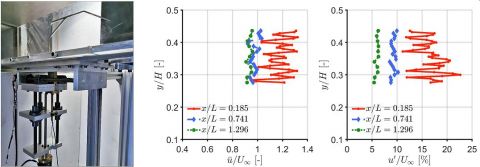

More than 20 samples have been tested in WAABLIEF (VKI) at mid-velocity (25 m/s) with a hotwire probe and PIV, providing mean-velocity and turbulence-intensity profiles, integral length scales and 2-point correlation lengths, upstream and downstream the samples.

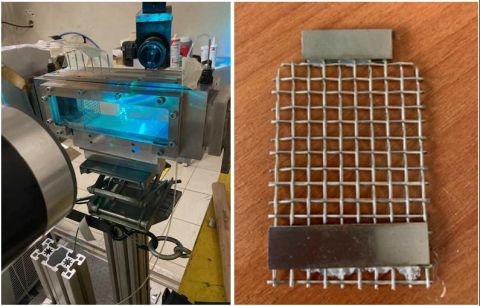

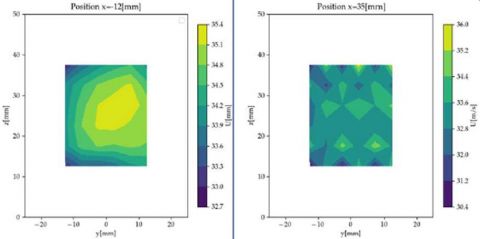

In parallel, the same fairings (as smaller samples) have been tested in B2A (ONERA) with LDV at slightly higher velocity (36 m/s) for pressure drop characterization. Then a selection of these samples has been subject to fine aerodynamic surveys with LDV.

All the collected information will be helpful for calibrating the models in the CFD/CAA solvers, as currently developed by ONERA, RWTH and Chalmers.

WAABLIEF facility – Wiremesh sample

WAABLIEF facility : hotwire set-up (left) - Mean velocity/turbulence intensity intensity traverse profiles at 3 distances downstream the wiremesh sample (right)

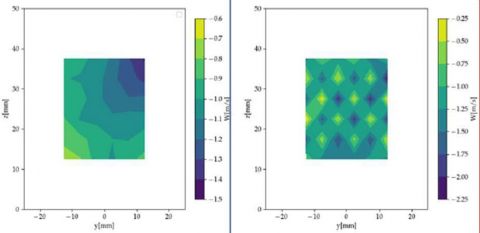

B2A facility – Wiremesh sample

B2A facility : LDV measurements of axial (top) and transverse (bottom) mean velocity upstream (left) and downstream (right) the wiremesh