Porous flow-through fairings for landing gear noise reduction:

experimental down selection by TU-Delft in A-Tunnel facility

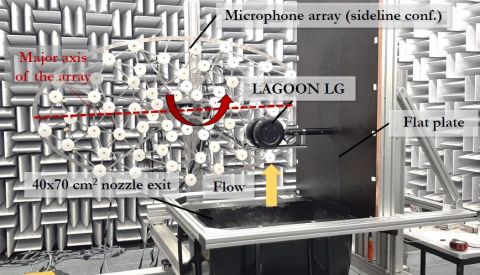

INVENTOR focuses on the use of porous flow-through fairings upstream the landing gear axle for noise mitigation purposes. Targeted concepts are wiremeshes, perforated plates, metallic wool and synthetic foams. One of the objectives is to select the fairings that provide the best noise reduction. To this aim, the fairings that have been precisesly characterized in WAABLIEF and B2A, have been subsequently tested in the aeroacoustic A-Tunnel facility at TU-Delft on a scaled 2-wheel landing gear model. Such model is representative of nose landing gears employed in short/medium range commercial and business aircraft and, as such, includes realistic elements such as brakes and torque link.

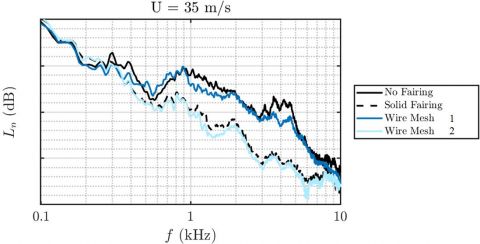

Far-field acoustic spectra were obtained from the integration of noise maps obtained with a 64-microphone array installed in sideline and flyover positions with respect to the landing gear. Additional mean flow oil visualizations were achieved.

Finally, PIV and hotwire measurements have been achieved on a selection of samples. These data will be used:

To select the most promising porous fairings; these will be further characterized in aeroacoustic tests at DLR (AWB windtunnel) on a realistic landing gear model with similar scale

To validate CFD/CAA numerical simulation of the fairing action on landing gear noise reduction.

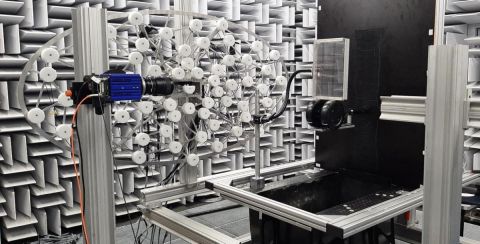

A-Tunnel set-up

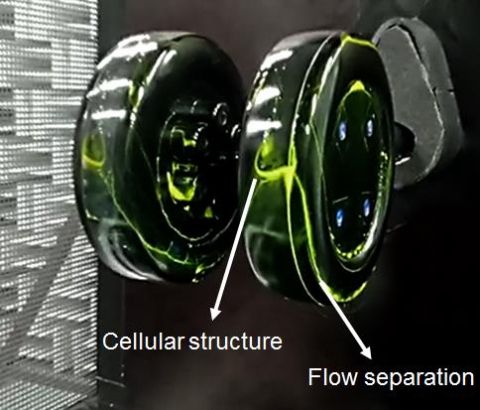

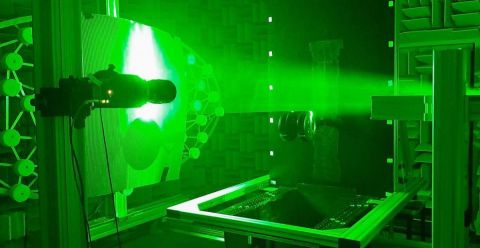

Left : Simplified landing gear equipped with a wiremesh fairing – Right : flow visualization

Farfield noise spectra measured without fairing (reference), with a solid fairing and with two different wiremeshes

A-Tunnel : PIV set-up